Assurance qualité sans étiquettes ni marquages

- Client

- Alitheon, Inc.

- Localisation

- Bellevue, Washington, États-Unis

- Date

- 2020

Le logiciel d’imagerie sans contact Alitheon permet l’identification et le suivi de pratiquement n’importe quel article, sans étiquettes, marquages ou emballages.

Identifiez et suivez clairement les articles

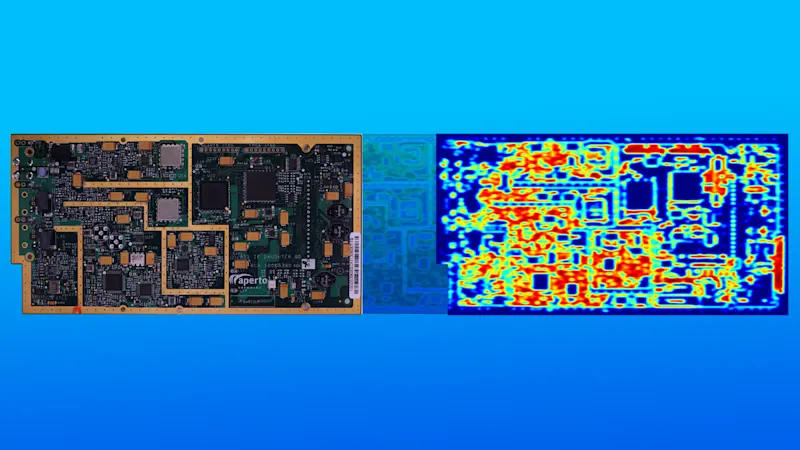

Pour l’assurance qualité, il est crucial de pouvoir identifier et tracer de manière unique chaque composant d’un produit. Habituellement, des codes-barres, des étiquettes ou des gravures sont utilisés à cet effet. Cependant, les articles produits en série tels que les fixations, les circuits imprimés, les pièces moulées ou les textiles ne permettent généralement pas de tels marquages.

Alitheon a été fondée pour résoudre ce problème grâce à une approche universelle de la traçabilité, en fournissant une sécurité au niveau des articles sans modifier la conception des produits ou les processus de fabrication.

Traçabilité via le cloud - de n’importe où

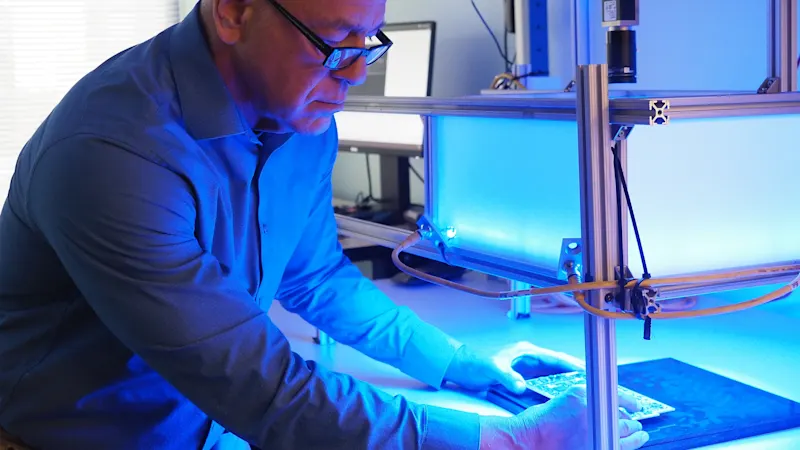

À l’aide d’une seule caméra dans l’usine ou sur le terrain, par exemple sur les cellules de la machine ou les postes de travail, la technologie Alitheon vérifie avec précision l’identité de pratiquement n’importe quel article en fonction de minuscules variations de caractéristiques à l’aide d’algorithmes logiciels. Grâce à la vision artificielle sans contact, le logiciel Alitheon analyse la surface de chaque article unique et génère un code numérique qui le distingue de millions d’articles apparemment identiques.

Cet identifiant FeaturePrint généré localement est disponible via les systèmes cloud. Il fournit un numéro de série virtuel faisant autorité qui peut être stocké, suivi et vérifié à l’infini tout au long de la vie d’un article - dans les usines, les canaux de distribution ou auprès des utilisateurs finaux via une application mobile.

Données d’image en phase avec la production

Alitheon utilise les caméras Basler' ace L et Classic dans ses composants FeaturePrint™ Automate et FeaturePrint™ Station dans un boîtier de machine pouvant être installé ultérieurement ou dans une unité de table. Ces dispositifs peuvent être utilisés dans la construction automobile ou dans l’assemblage correct de cartes de circuits imprimés, entre autres applications. Les caméras Basler transmettent des données d’image au traitement FeaturePrint à chaque étape de la production, à une fréquence d’images qui suit le rythme des lignes de production. Cela garantit un contrôle continu de la qualité.

La suite logicielle pylon aide Alitheon à tester et à valider ses systèmes hors site, réduisant ainsi les retards et les coûts de déplacement.

Avantages dans l’environnement manufacturier

Matériel et logiciels de haute qualité et facilement disponibles

Surveillance et contrôle en toute sécurité du flux de production tout au long des différentes étapes de production

Génération de données importantes pour l’entreprise

Possibilité d’adaptation dans les lignes de production existantes avec des caméras industrielles pour un fonctionnement continu

Equipement des anciennes usines d’un nouveau système de contrôle numérique pour le suivi des marchandises

Flexibilité technique telle que la prise en charge du SDK pour Linux

Produits pour cette solution

Vous cherchez à mettre en œuvre une solution comparable ? Ces produits vous aideront.