Camera Sizes: the Smaller, the Finer

Ever have that inescapable need for a little something sweet? Good things in small packages applies not just to fine confectioneries, but also to the world of industrial machine vision: Sugarcube is a term that has grown in importance in the industry in recent years. It represents a trend in vision technology towards miniaturization.

The sugarcube in industrial machine vision

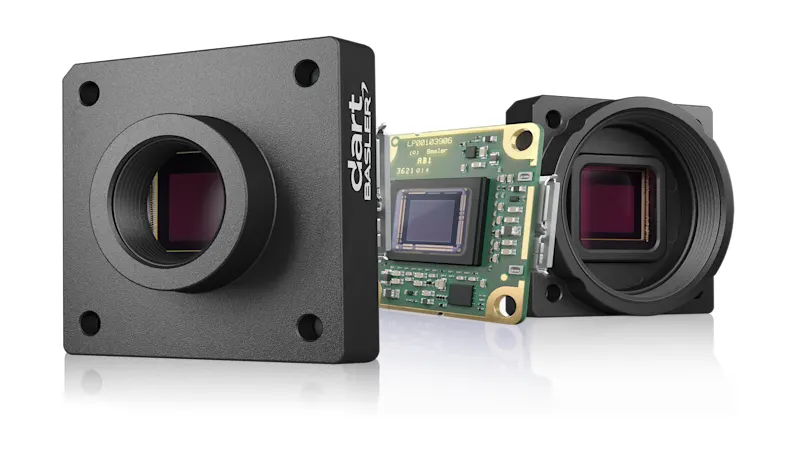

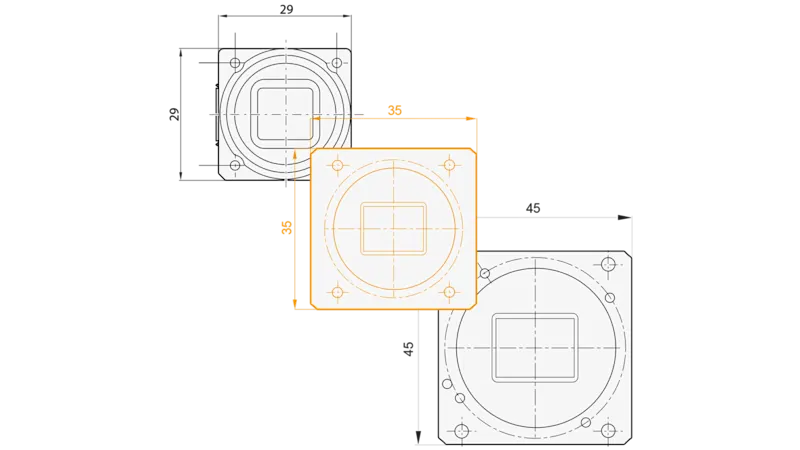

The term refers to small cameras sized at 29 mm x 29 mm, which has become an unofficial but de-facto standard. The so-called "Sugarcube" design encompasses industrial cameras in the entry level and lower mainstream segments, covering a variety of classic operations in many different markets such as Medicine, Traffic and Transportation and Retail, as well as for Quality Assurance and Automated Optical Inspection in the field of factory automation.

Small format, grand innovation

The trend toward small form factors was observed as far back as 20 years ago in analog cameras, with echoes during the rise of FireWire and later Gigabit Ethernet. It's unlikely to end with current modern interface technologies such as USB 3.0. All notable technical innovations, such as high-resolution sensors and comprehensive firmware features, are packed onto or into these minute dimensions. Analog cameras at this point can now also process their image data within a small housing instead of sending it on to an external processing unit.

Important considerations

When planning a new or redesigning an existing machine vision system, care should be taken from the start to build around small sizes so as to avoid space issues later.

For redesigns in particular, small footprints should be maintained. Switching over to large formats can bring major mechanical challenges.

Small sensors = small cameras

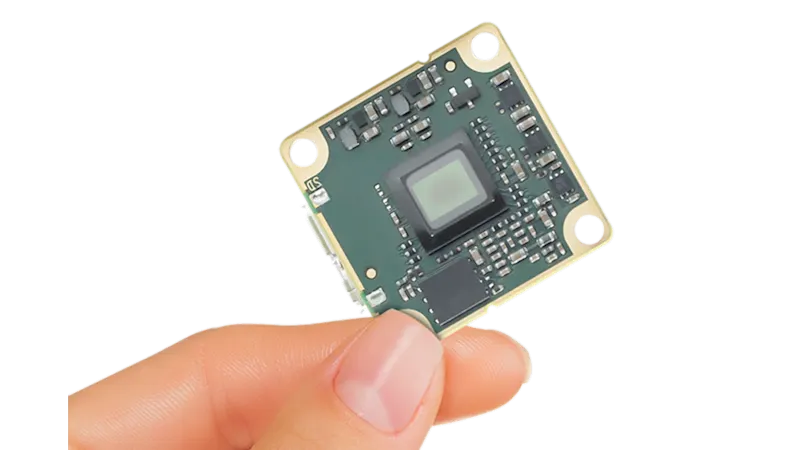

A camera's size is reflective at least in part by the size of its sensor. Larger sensors, typically using CCD technology, do not work in these small standard sizes. Such cases are becoming increasingly rare as the machine vision world shifts further and further toward CMOS for its sensor technology. Small, extremely powerful sensors with small pixel sizes are selling better than ever on the market, and are expected to replace the standard 29 mm x 44 mm size commonly seen today.

Productive, affordable, flexible

The small 29 mm x 29 mm format is the best way to achieve top throughput rates at the lowest costs possible. This size has established itself not just for its external appearance (camera front), but also for its drilling pattern. Most camera makers have harmonized their offerings to work with it, which gives customers significantly more flexibility.

Traditional CCD sensors were typically built around larger dimensions, such as 40-45 mm x 40-45 mm. The trend toward smaller CMOS sensors means those larger dimensions are likely to shrink into niche areas of the machine vision market.

Their replacements will be the ultra-compact 29 mm x 29 mm cameras as well as the approx. 35 mm x 35 mm format, supported by the latest generation of smaller, high-resolution CMOS sensors.

Customers benefit from the compact housing sizes:

A small camera footprint within systems cuts weight and thus increases the speed of applications. The lighter the robot arm, for example, the faster and more flexibly it can move.

Small camera formats also free up more space. This can be used to shrink the system or for easier physical access to the cameras as needed.

Small-format cameras rely on the cost benefits inherent to smaller sensors. Because they require more silicon, sensors with large sensor surfaces are significantly more expensive than small sensors.

Remarkable technological progress in industrial machine vision is really being driving in the small, compact sensor formats, and in particular in modern CMOS sensors.

Larger camera applications, typically CCD based, continue to perform their tasks in specific highly complex areas, but small-format sensors and cameras are primed to assume the majority of machine vision responsibilities going forward.