Compatibilité de nos composants

Basler propose tous les composants nécessaires à un système de vision d’un seul tenant. Pour garantir une fonctionnalité optimale avec différentes applications et outils, nous veillons à ce que tous les composants fonctionnent ensemble sans problème.

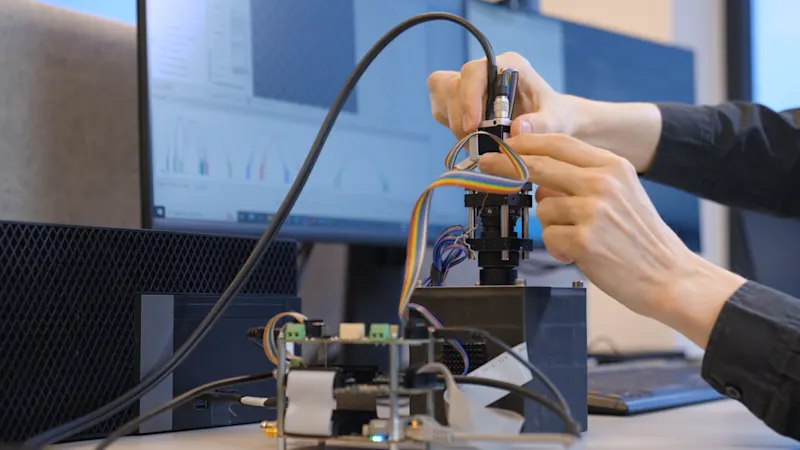

Tests & de composants actifs/passifs

Nous assurons la compatibilité de tous nos composants grâce à des tests systématiques.

Composants passifs

Sur la base de nos spécifications techniques, nos composants passifs tels que les objectifs, les filtres et les montures de caméra sont soumis à des tests réguliers de fonctionnement et d’interopérabilité. Nous effectuons régulièrement des audits de fournisseurs afin de garantir un niveau de qualité élevé et constant, même pour les composants achetés. Nous effectuons non seulement des tests fonctionnels, mais nous vérifions également la compatibilité de tous les composants avec nos caméras. Nous fournissons également toutes les certifications nécessaires.

Composants actifs

Pour les composants actifs (caméras, éclairage, logiciels), tout, du plus petit composant jusqu’au plus petit, est vérifié avec précision en plusieurs étapes définies. L’alignement des capteurs des caméras, par exemple, est vérifié dans le cadre de tests automatisés. Des tests de température sont effectués pour certains modèles. Enfin, nous effectuons un contrôle entièrement automatisé avec notre outil de test développé par nos soins. Tous les paramètres critiques sont vérifiés. Ces tests automatisés sont personnalisés pour chaque plate-forme de caméra Basler.

Assurer systématiquement l’interopérabilité

Lors du développement de nouveaux systèmes de vision, Basler dispose d’une unité centrale qui gère et définit toutes les exigences jusqu’à la validation. Cela signifie que les idées de produits spécifiques sont converties en exigences système de base. Ceux-ci servent ensuite de paramètres de liaison pour les différents composants. De cette façon, ils agissent comme une sorte de pierre de touche pour la qualité et la stabilité du système.

De plus, notre communauté de systèmes de vision (notre groupe interdisciplinaire de développeurs et d’architectes) définit et élargit en permanence le cadre des spécifications du système. Grâce à ce cadre, nous garantissons la fiabilité individuelle et l’aptitude à l’utilisation dans les systèmes de vision industrielle. Avec un accent particulier sur la compatibilité et le bon fonctionnement avec tous les autres composants.