Robot autonome pour la logistique de production

La vision 3D et la lecture de codes permettent une alimentation intelligente des lignes

- Client

- Magazino - Une entreprise Jungheinrich

- Localisation

- Munich, GER

- Date

- 2023

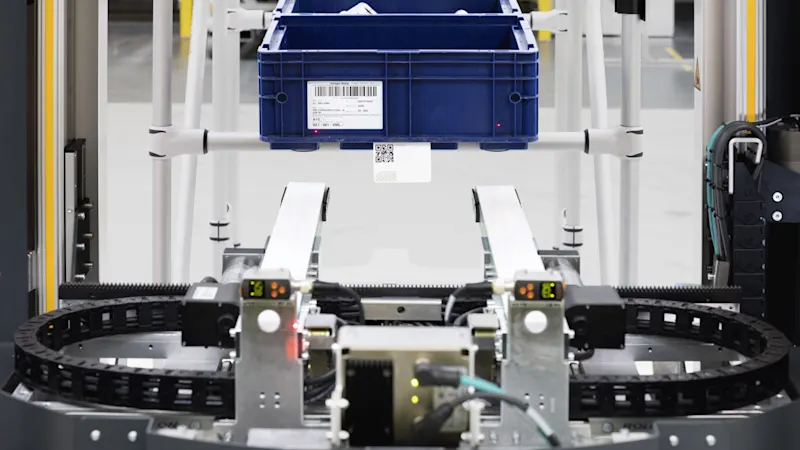

Le robot SOTO, entièrement autonome, automatise l'approvisionnement en matériaux dans le domaine de l'intralogistique. La technologie de caméra 3D Basler contrôle les pinces avec la technologie de convoyage pour prendre, tourner ou déposer de petits supports de charge. Différents codes marquent les emplacements de stockage et les KLT.

Approvisionnement en matériaux automatisé

Malgré le niveau élevé d'automatisation des lignes de production industrielle, le réapprovisionnement est encore souvent effectué manuellement. Les trains remorqueurs et les simples véhicules guidés automatiquement (AGV) atteignent ici leurs limites, car le chargement et le déchargement doivent toujours être effectués manuellement. L'AMR SOTO apporte une solution : il transporte les petits porteurs de charge (SLC Small Load Carrier) de manière totalement autonome - directement de l'entrepôt à la ligne d'assemblage, sans intervention manuelle.

Manipulation précise des petits porteurs (KLT)

Qu'il s'agisse d'un flow rack, d'un convoyeur à bande ou d'un train de remorquage : SOTO transfère ou retire les KLT avec une grande précision. Il peut réagir de manière flexible à différentes positions et hauteurs. Cela est dû à un système de préhension intelligent : Deux pinces, qui sont équipées de bandes transporteuses rotatives , peuvent saisir, déposer et faire pivoter les KLT. Par exemple, les KLT peuvent être déposés sur le côté long et les vides récupérés sur le côté court.

Prélèvement indépendant des marchandises grâce à la commande 3D ToF

Le système de préhension SOTO est contrôlé par des données de profondeur en 3D : Une caméra Basler ToF est installée à l'arrière du système de préhension de manière à enregistrer et à mesurer la scène d'enlèvement ou de chargement. Des distances de 10 cm à 1,5 m doivent être mesurées en temps réel afin de déterminer les coordonnées du bord avant d'un KLT ou d'une place de parking. Les deux pinces sont commandées de manière fiable et en quelques millisecondes en fonction des coordonnées.

Une seconde caméra 3D ToF est intégrée dans le "plafond" de SOTO et prend en charge le réglage fin des pinces. Si un KLT est détecté légèrement de travers pendant l'alimentation, l'une des deux pinces peut être spécifiquement déplacée plus lentement ou plus rapidement pour corriger la position en temps réel. Cela garantit une alimentation précise et régulière, pour une manutention fiable et efficace.

Il était clair pour nous que nous avions besoin d'une imagerie 3D pour un contrôle fiable des pinces. La caméra blaze Time-of-Flight Basler a été notre premier choix.

La fonction HDR double exposition permet de maîtriser les reflets de manière fiable.

Les réflexions lumineuses posent un problème dans les environnements industriels où les conditions d'éclairage sont changeantes, car chaque surface réfléchit la lumière, surtout à partir d'un angle d'incidence faible.

La caméra Basler Time-of-Fligh avec fonction HDR résout ce problème grâce au Mode Dual Exposure: deux images avec des temps d'exposition différents sont combinées, ce qui permet de capturer avec précision les objets très réfléchissants et ceux qui le sont moins. Le résultat est un nuage de points 3D détaillé, quels que soient le reflet, le matériau ou la distance.

Cette caméra est donc particulièrement adaptée aux environnements de production et de logistique dynamiques, où une qualité d'image constante est cruciale malgré des conditions d'éclairage complexes.

Les codes-barres et les codes QR permettent de suivre les KLT et d'identifier les places de stationnement.

Les codes-barres et les codes QR sur les KLT et les tables de convoyage sont lus à l'aide d'un traitement d'image 2D et permettent un suivi de bout en bout dans les systèmes modernes de flux de marchandises.

Les KLT sont identifiées et suivies à l'aide de codes

Les codes contiennent des informations telles que le lieu de stockage, la destination ou même les numéros de lot. , les lisent et transmettent les informations à un système de gestion d'entrepôt. Le robot autonome SOTO est équipé d'une caméra à balayage de zone Ace 2 afin que chaque mouvement des KLT puisse être documenté.

À propos de Magazino

Magazino GmbH - une entreprise de Jungheinrich, développe et construit des robots intelligents et mobiles qui peuvent percevoir leur environnement, prendre leurs propres décisions et saisir des objets. Les robots autonomes travaillent en parallèle avec les humains et rendent les processus plus flexibles et plus efficaces dans les domaines du commerce électronique, de la mode et de la logistique de production. Avec 130 employés sur son site de Munich, Magazino est l'une des plus grandes équipes de robotique avancée en Europe. Magazino fait partie de Jungheinrich AG depuis 2023.