Image Processing in Battery Cell Manufacturing

Machine vision provides quality control

In the production of battery cells, ensuring high quality during all process steps and reducing material waste are crucial. Digital image processing enables the reliable detection of even the smallest defects. Our solutions help produce safe, high-quality battery cells to meet the challenges of electric mobility.

Prestazioni e velocità elevate

Tecnologia di ripresa innovativa e ad alte prestazioni per metodi di produzione all'avanguardiaDurevole e affidabile

Con il tasso di guasti più basso del settore, i nostri sistemi di telecamere sono sinonimo di affidabilità nel funzionamento 24 ore su 24, 7 giorni su 7.Integrazione semplice

Tutti i nostri componenti sono compatibili e facili da collegare ai sistemi di destinazione utilizzando il software pylon.Disponibilità e consegna affidabile

Catene di approvvigionamento stabili assicurano la disponibilità a lungo termine dei nostri prodotti e prevengono i tempi di inattività della produzione.

Find out in our webinar:

How machine vision is used for quality control in the production of battery cells

More about typical machine vision applications in battery cell production

How you can increase the efficiency of your production by using machine vision

Different cell types

The main application for lithium-ion battery packs is electric mobility. Though there are three types and formats in use, the functional principle of all types is essentially the same. The main differences are in the design, requirements, and materials used.

Battery cell manufacturing involves four main process steps

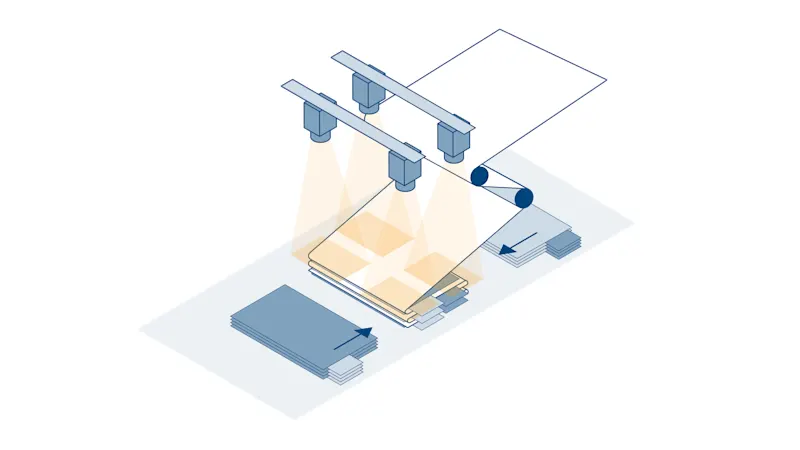

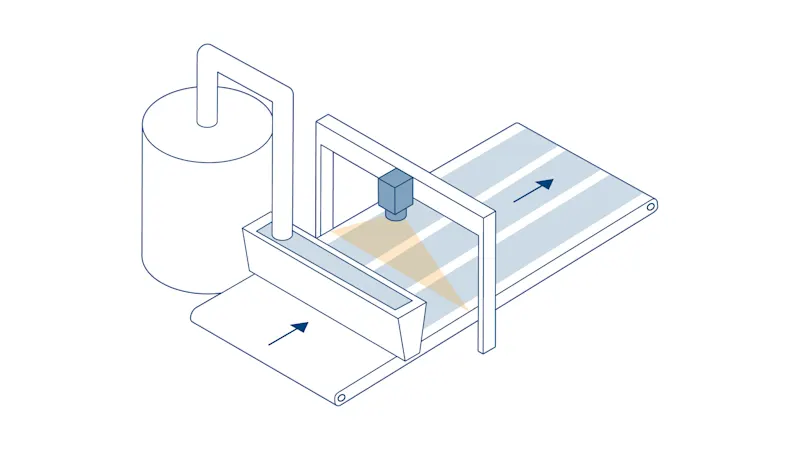

Lithium-ion battery cell production consists of four main process steps: electrode production, cell assembly, cell finishing, and battery pack assembly. The electrode production and cell finishing process steps are largely independent of the battery cell type, while cell assembly distinguishes between pouch or prismatic cells and cylindrical cells. Regardless of the cell type, the smallest unit of any lithium-ion cell consists of two electrodes and the separator that divides them from one another. In between is the ion-conducting electrolyte.

Machine vision ensures product quality and process stability

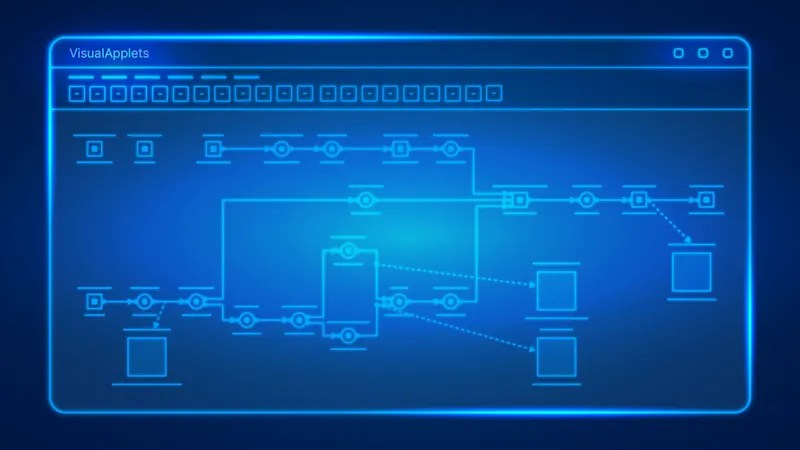

Machine vision systems provide valuable information during the production process, including inspecting materials and ensuring process steps are correctly executed. Different solutions are available depending on your application needs. By combining our frame grabber-based systems with VisualApplets and our high-sensitivity line scan cameras, the resulting vision system can easily cope with the high speeds found in electrode production. High-resolution ace 2 X visSWIR cameras inspect the structures of separator foils inside the cell. Our area scan cameras, working in conjunction with pylon vTools, check that the cathode and anode are correctly positioned on top of each other during the winding of prismatic cells. Catching even the smallest defect is critical, since accurate error tracking increases productivity.

Where is vision used in battery cell manufacturing?

Use cases in battery cell manufacturing

Machine vision helps ensure the quality of processed materials and minimizes possible material waste. Our solutions can help.

Prodotti più popolari

Per applicazioni di visione in questo settore, i seguenti prodotti Basler sono spesso la scelta migliore: